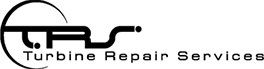

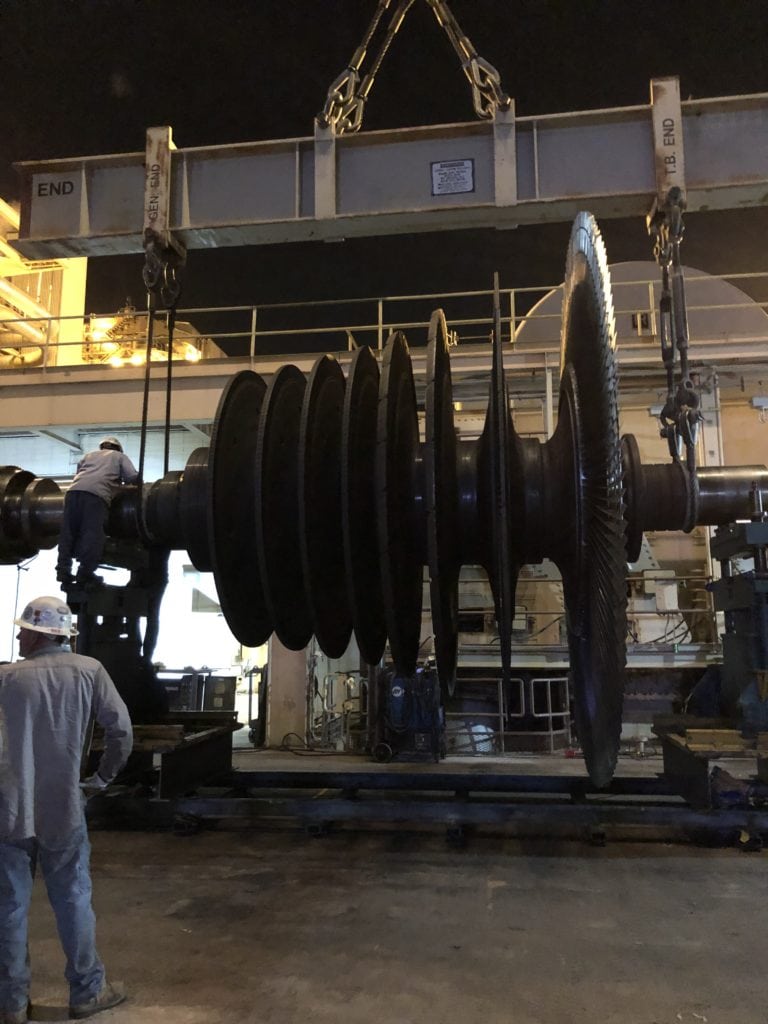

TRS is primarily involved in the specialty type of repairs on Steam, Gas and Hydro turbines. Our customers are in the power generation industry and include the major utilities as well as the cogeneration, geothermal and independent power producers. We also service industrial, petrochemical and municipal sectors. These repairs consist of on site machining of turbine components i.e. rotor shafts, seals and other components, which generally require extremely close tolerances and extra fine finishes.

Specific Services Provided Include:

- Turbine Rotor Repairs

– Blade / bucket replacement & repair

– Journal & thrust grinding

– Coupling face & bolt hole machining - Steam Path Repairs

– Nozzle, diaphrams & steam seals - Oil Deflectors & Hydrogen Seals

– Replace seals & housing repairs - Casing & Shell Repairs

- Stud Removal

- Pumps, Compressors & Heaters

– Line boring, flange face machining - Turbine Valves

– Seat removal & bore machining - Full Range of on site Machining Equipment

– 100 ton portable lathe, portable VTL, portable machine shops, low-speed balance, boring bars, flange facers, milling machines & journal cages

Download Our Machining Flyer

Download Our Machining Flyer